Laser rods - Erbium doped

Er:YAG

Er:YAG crystals with high doping concentration of Er3+ ions are typically used for lasing at 2936 nm.

The main feature of this wavelength is high absorption in water and hydroxyapatite. Thus Er:YAG crystals are mostly applicable for construction of the dental surgery and aesthetic surgery lasers.

Low-doped Er:YAG laser crystals are used for producing of the eye-safe radiation at 1645 nm by in-band pumping with semiconductor laser diodes at 1,5 microns. The advantage of such a scheme is low thermal load corresponding to low quantum defect.

|

|

| Material characteristics | ||

|---|---|---|

| Crystal structure | cubic - la3d | |

| Laser wavelengths | 4S3/2→4I9/2 | 1645 nm |

| 4I11/2→4I13/2 | 2936 nm | |

| Pump bands | 0.6-0.8 µm | 1.53 µm |

| Thermal conductivity | 11 W/m K | |

| Refractive index at 632 nm | 1.83 | |

| Temperature dependence of refractive index | 7.8 10-6/K | |

| Fluorescence lifetime | 230 µs | |

| Emission cross section at 2940nm | 3×10-20 cm2 | |

| Design | ||

| Rod diameter | 2 – 5 mm | |

| Rod length | Up to 120 mm | |

| Er doping concentration | 0.2% - 50% at. | |

| Polishing | Barrel surface fine ground or polished. Perpendicular or wedged ends. Polishing according to DIN and MIL standards. |

|

| Coatings | Ion assisted | |

Er:YAP

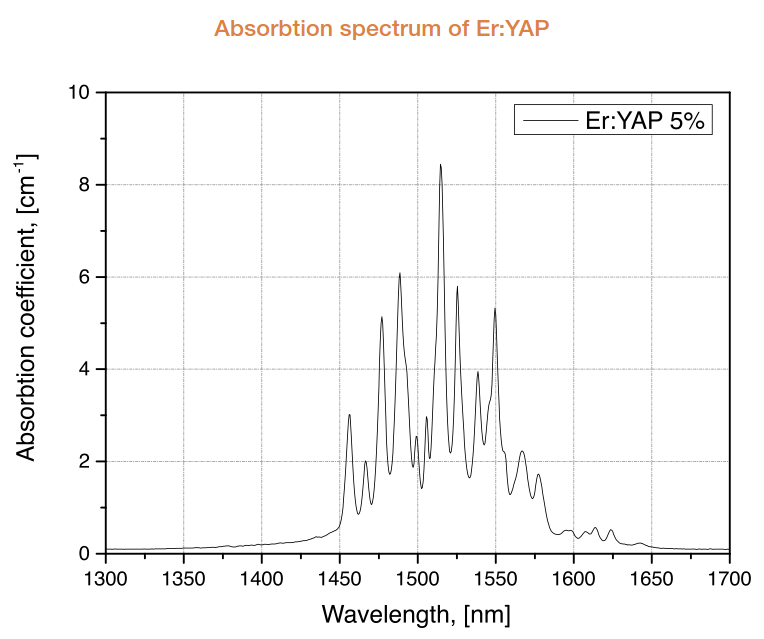

Yttrium aluminium oxide YAlO3 (YAP) is an attractive laser host for erbium ions due to its natural birefringence combined with good thermal and mechanical properties similar to those of YAG.

Er:YAP crystals with high doping concentration of Er3+ ions are typically used for lasing at 2,73 microns.

Low-doped Er:YAP laser crystals are used for of the eye-safe radiation at 1,66 microns by in-band pumping with semiconductor laser diodes at 1,5 microns. The advantage of such a scheme is low thermal load corresponding to low quantum defect.

|

|

| Material characteristics | ||

|---|---|---|

| Crystal structure | orthorhombic - Pbnm | |

| Laser wavelengths | 4S3/2→4I9/2 | 1.66 µm |

| 4I11/2→4I13/2 | 2.73 µm | |

| Pump bands | 0.6-0.8 µm | 1.53 µm |

| Thermal conductivity | 11 W/m K | |

| Refractive index at 632 nm | 1.93 | |

| Crystallographic orientation | b-axis ref. to Pbnm convention | |

| Design | ||

| Rod Diameter | 2 – 5 mm | |

| Rod Length | Up to 100 mm | |

| Doping concentration | 1 % - 50% at. | |

| Polishing | Barrel surface fine ground or polished. Perpendicular or wedged ends. Polishing according to DIN and MIL standards. |

|

| Coatings | Ion assisted | |